J-shaped bent tempered glass

High-quality glass is heated to approximately 650℃ and then rapidly cooled, creating a state of high compression (compressive stress) on the surface while maintaining a compensating force (tensile stress) at the core. This surface compressive stress resists various tensile forces that cause glass breakage, significantly enhancing the glass is mechanical strength. Compared to ordinary glass, its impact resistance, bending strength, and thermal shock resistance are increased by 3-5 times. When broken, the glass fragments form sharp-edged particles, minimizing the risk of injury. Therefore, tempered glass is a legally mandated safety glass.

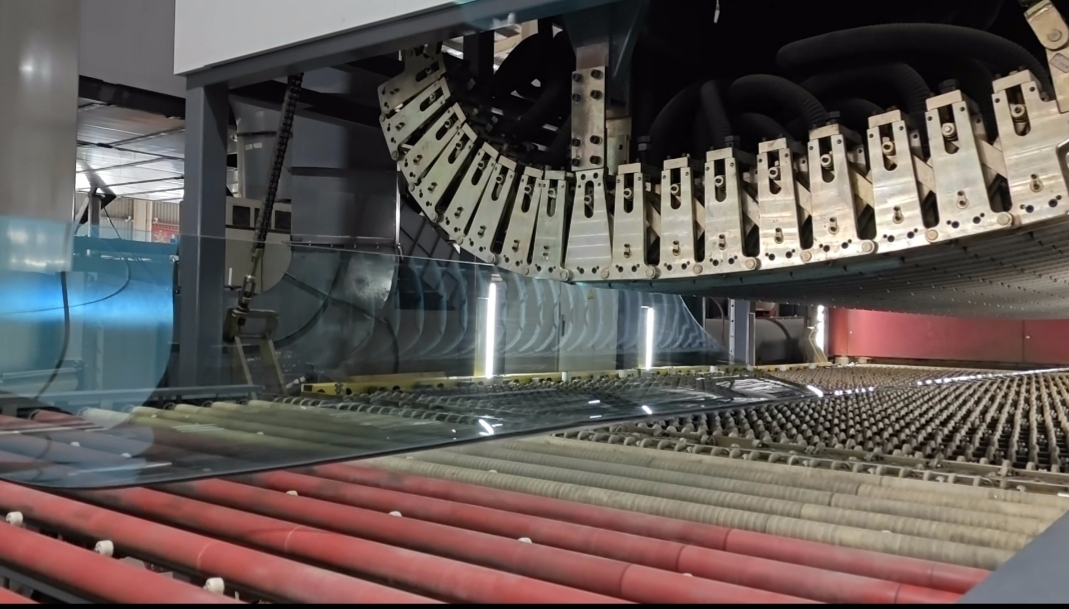

Flat-Curved Integrated Tempering Furnace Dimensions: 4m x 6.5m 3.66m x 16m

Hot-Dip Furnace Dimensions: 3.66m x 16m

Autoclave Dimensions: 3.66m x 20m

Insulated Glass Line Dimensions: 3.66m x 20m

Cutting Line Dimensions: 3.66m x 20m